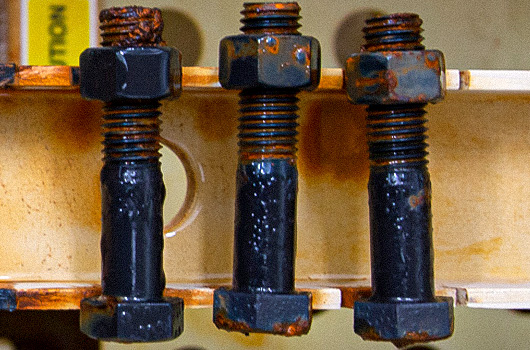

Cerakote, a ceramic-based coating, is engineered for exceptional resistance to corrosion, abrasion, and chemicals, making it a top choice for industries requiring long-term protection. In contrast, Teflon and Xylan, both fluoropolymer-based coatings, offer non-stick and low-friction properties but may fall short in extreme corrosion resistance, especially in highly abrasive or high-temperature conditions. Understanding these differences is crucial for selecting the best coating for specific applications.

Siga leyendo para saber más: