NEW FROM CERAKOTE®: ADVANCED CERAMIC DRY FILM LUBRICANT THAT REDEFINES PERFORMANCE

CERAKOTE® is proud to introduce its latest innovation in high-performance surface coatings: a ceramic-based Dry Film Lubricant (DFL-200), PFAS-free and engineered for long-term durability, efficiency, and protection.

Formulated with advanced ceramic and solid lubricant systems, this new coating delivers exceptional performance in high-friction, high-wear environments—without relying on fluoropolymers or PFAS compounds.

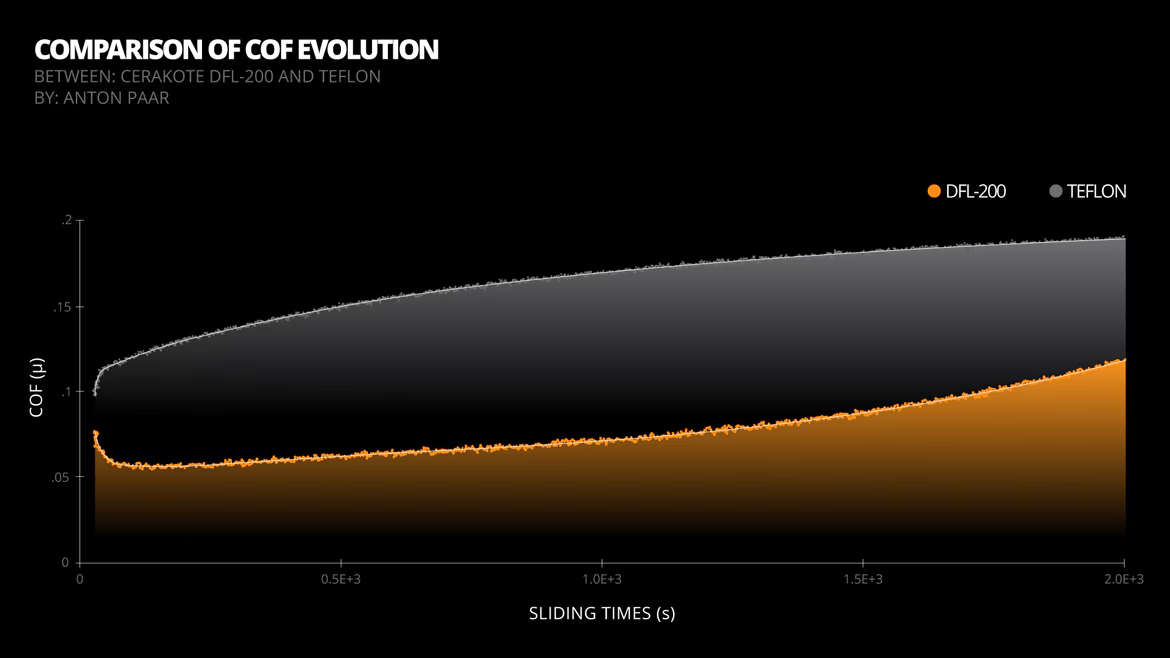

UNMATCHED LUBRICITY

Independent testing confirms what performance engineers have been waiting for: DFL-200 is over 40% slicker than Teflon®.

This remarkable reduction in surface resistance—achieved through precision-formulated ceramic and solid lubricants—translates to smoother part movement, enhanced mechanical efficiency, and dramatically lower friction coefficients.

KEY PERFORMANCE BENEFITS

- Ultra-Low Friction: Third-party lab tested using TRB³ per ASTM G99-17 and ASTM G133 standards. Results show DFL-200 demonstrated a significantly lower coefficient of friction (COF) compared to Teflon®, validating that it is over 40% slicker.

- Outstanding Wear Resistance: Withstands extreme contact, abrasion, and mechanical load, extending component life.

- REACH/RoHS Compliant: PFAS-free formulation that meets modern regulatory expectations without compromising performance.

- Superior Chemical Resistance.

- Excellent Alternative to Molykote®, Teflon®, and Xylan® Products.

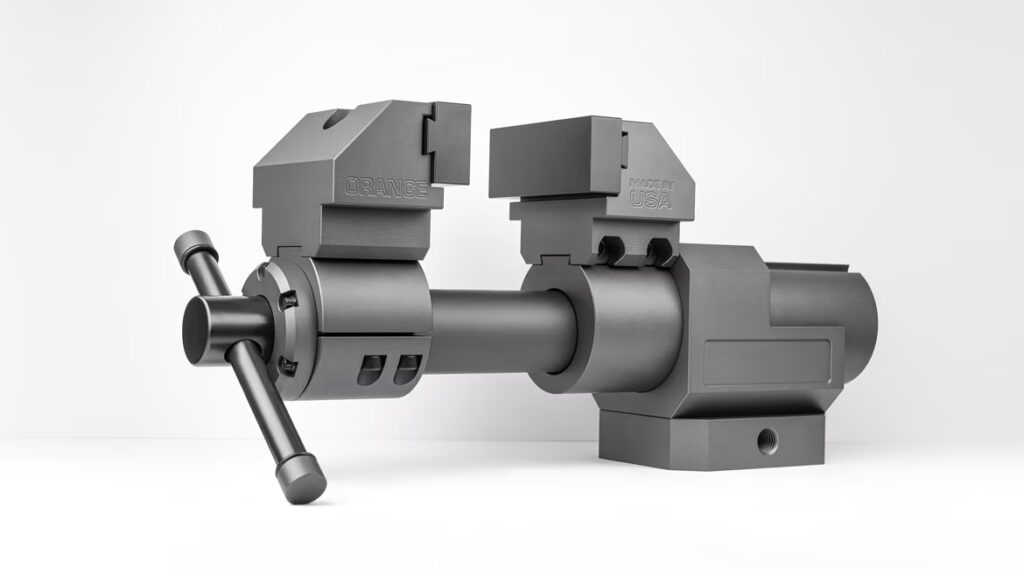

BUILT FOR DEMANDING INDUSTRIES

From aerospace systems and firearms to automotive assemblies and industrial machinery, DFL-200 is engineered to excel where precision, reliability, and protection are critical.

- Aerospace: Low-friction, non-outgassing coating for critical assemblies

- Defense: Durable finish for high-wear weapons and gear

- Automotive & EV: Ideal for lightweight, high-efficiency drivetrains

- Industrial & Robotics: Smooth motion under heavy use with no contamination risk

ENGINEERED FOR PRODUCTION EFFICIENCY

Its cutting-edge formulation features a fast cure time and low-temperature curing schedule, optimizing manufacturing processes while setting a new standard for performance and efficiency. The coating applies easily, cures consistently, and integrates seamlessly into both small-scale and high-volume production workflows.

For manufacturers seeking next-generation friction control and surface protection, CERAKOTE® DFL-200 delivers a proven, high-performance, PFAS-free solution that is PFAS-free solution that is over 40% slicker than Teflon®.